Your Complete Asphalt Mixing Plant Buying Guide

Industry News

2025/11/28

Getting an asphalt mixing plant is a major move for any building firm. It can change how your jobs go and hit your profits hard. If you run projects, do contracting work, or own a company that lays roads or sets up structures, this guide points you in the right direction. We will go over what to watch for, usual mistakes, and ideas to pick smart. See it as your path to gear that matches what you do and helps your name in the trade.

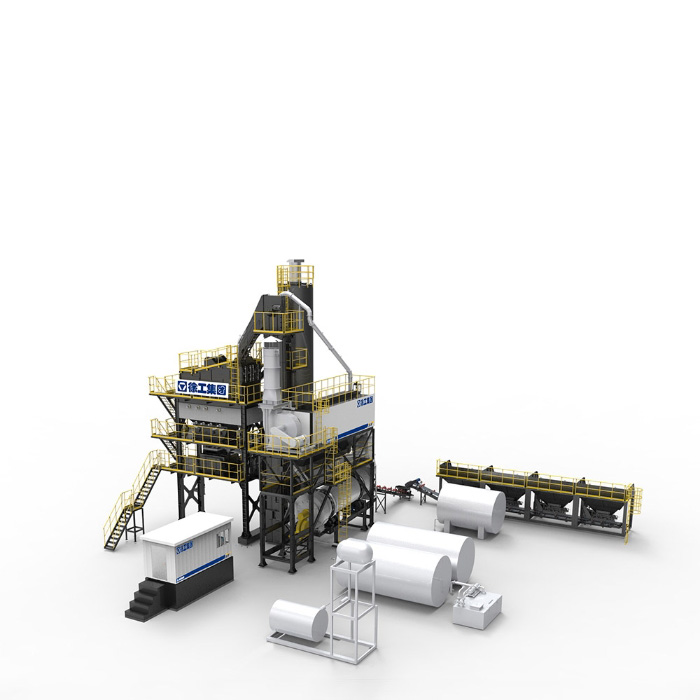

Understanding Asphalt Mixing Plants

Asphalt mixing plants play a big part in making roads. They mix rocks, glue, and stuff to make asphalt for covering surfaces. Picking the right one leads to easy work and good outcomes on the job.

What is an Asphalt Mixing Plant?

In simple terms, an asphalt mixing plant warms and stirs stuff to make hot asphalt mix. It begins with putting cold rocks into heaters, then blending them with warm tar. This method gives steady quality for big roads, car lots, or landing strips. Why care? A solid plant reduces junk and keeps your group busy. Picture wrapping up tasks quicker with less trouble from stops.

These plants show up in different scales, from tiny ones for nearby fixes to huge ones for big deals. They deal with plain mixes or special ones with extras for toughness.

Types of Asphalt Mixing Plants

Figuring out the kinds helps you cut down choices. Here is a fast list:

Asphalt mixing equipment can be classified by mixing method into Batch Mix Plants and Drum Mix Plants .

- Batch Mix Plants: They make asphalt in groups, so you control each batch well. Fine for tasks that need various mixes. They fit city spots where top-notch beats hurry.

- Drum Mix Plants: They keep going without stops, mixing in a turning barrel. Quicker and easier, good for lots of work like long paths. Not as bendy on changing mixes, though.

Based on the method of transportation, they can be classified into Stationary, semi-Stationary, and mobile types.

- Mobile Plants: You can carry these around sites. Right if your jobs are spread far.

- Stationary Plants: Set in one place for steady use. They hold more but take time to put up.

- Semi-StationaryPlants:The equipment is mounted on trailers and assembled at the construction site; this type is commonly used in highway construction.

Choose by how you work. Say, if you take on mixed deals, a batch kind could work best.

Key Factors to Consider When Buying an Asphalt Mixing Plant

Take your time on the pick. Think about these points to fit the plant to your goals. A bad choice might cause breaks or added bills.

Capacity and Production Needs

Start by checking how much asphalt you want each day. Plants go from 40 tons an hour for small teams to over 300 for large ones. Guess too low, and you get holds. Go too high, and you spend on gear that sits.

Look at your jobs. City fixes? Pick smaller. Road deals? Go bigger. Chat with your crew on busy times.

Mobility: Stationary vs. Mobile

Where do you plan to run it? Fixed plants stay in spot, giving firm base for long runs. They take heavy stuff fine.

Movable ones pack up for trips. Useful for workers who shift often. Yet they could cost extra at first from the build.

Weigh travel. Gas for shifting a movable unit piles up, but it cuts setup hours.

Fuel Efficiency and Environmental Impact

Fuel eats money quick. Seek plants with good burners that burn less oil or gas. Some change to clean picks like earth gas.

Look at smoke. New plants follow tight laws, cutting dirt. This aids the world and shows your firm as earth-friendly. Buyers see when you put green first.

Quality of Components

Check the make. Tough bodies fight shake wear. Good stirrers give even mixes, no weak places in covers.

See controls. Number screens make runs simple, with warnings for problems. Strong bits mean less fixes, so your team stays on tasks.

After-Sales Support

After you buy, what next? Fine sellers give lessons, extra bits, and fast mends. No help, a stop could freeze your job.

Ask on guarantees. Good backup turns gear into a lasting help, making your firm seem steady.

Budgeting for Your Asphalt Mixing Plant Purchase

Cash decides. Set your spend to skip shocks. Split into first buys and running fees.

Initial Costs

The plant is the main spend. Costs change by scale and extras—think $100,000 for plain to millions for fancy.

Add ship, setup, and ground work. Fees if from abroad. Here is a rough chart:

| Component | Estimated Cost Range (USD) |

| Basic Plant | 100,000 – 500,000 |

| Advanced Features | 500,000 – 2,000,000 |

| Installation | 50,000 – 200,000 |

| Shipping | 20,000 – 100,000 |

Throw in taxes and any special changes.

Operating Costs

Keeping it going cuts into gains. Fuel, power, and hands lead the pack. Good models drop fuel by 20% or so.

Upkeep counts too. Usual checks stop big fixes. Set aside for bits—aim 5-10% of plant worth each year.

Look ahead. A costly plant might save with less stops and better run.

Evaluating Suppliers for Your Asphalt Mixing Plant

The seller matters like the gear. A good one stands by you, aiding your firm to grow.

Reputation and Experience

See their past. Time in trade means they fixed real issues. Check talks from other buyers.

Go to their places or speak to old clients. A seller with good name builds faith, shows on your mark.

Customization Options

No one fit for all. Fine sellers adjust plants for you—like add dust stops or more hold.

This custom touch makes your work shine, gives you lead in offers.

Meet MachPlaza: Your Trusted Asphalt Mixing Plant Supplier

Before we end, talk about MachPlaza. As a main shipper of build gear from China, MachPlaza gives full sets: machines, bits, and adds. Their group aims for great help, good costs, and fast sends. With big links of partners, they make fits for what you want. They hold to “guaranteeing customer operations” with close, kind aid over all stages—from before buy to way after. If you seek asphalt mixing plants, mail info@machplaza.com for job aids, goods, or bits. They focus on long bonds around the world.

Conclusion

Choosing a fine asphalt mixing plant comes to knowing what you need and picking wise. It lifts your speed, drops costs, and builds your place in trade. With good plan, you set path for wins. Set to go? Take this guide as start.

FAQs

What should I look for in an asphalt mixing plant buying guide?

Watch for hold, move, and fuel burn. Fit to your task kinds for top outcomes. Guides like this spot main traits that match your work.

How do I choose between types of asphalt mixing plants?

Think on your jobs. Batch plants fit mixed blends; drum for steady make. Movable picks for often shifts.

Why is after-sales support important when buying an asphalt mixing plant?

It holds your plant smooth. Fast bits and lessons mean less breaks, aid your firm stay sure.

What’s the average cost in an asphalt mixing plant buying guide?

Goes from $100,000 to over $2 million, by scale. Count running fees too for whole view.

How can an asphalt mixing plant improve my construction business?

It gives steady top, hurries tasks, and cuts junk. This grows your name and gets more deals.