What Is an Asphalt Mixing Plant? Your Essential Guide

Industry News

2025/10/17

Ever wondered how those smooth highways and sturdy parking lots come together? It all starts with the right mix. If you’re in construction or just curious about the gear behind our roads, knowing what an asphalt mixing plant does can open your eyes. These machines play a big role in building durable surfaces that last. Let’s break it down step by step, so you can see why they matter for your projects.

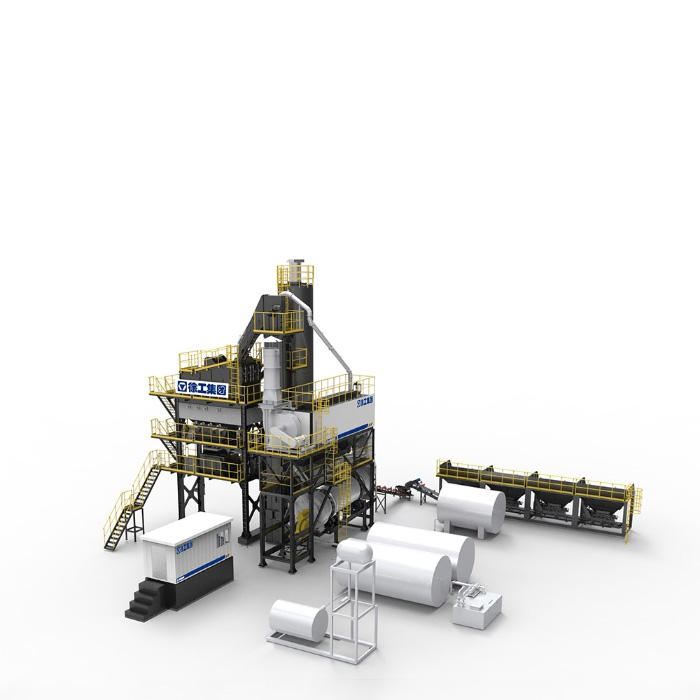

Defining an Asphalt Mixing Plant

At its heart, an asphalt mixing plant is a setup that blends raw materials into the blacktop we drive on. Think of it as a factory on wheels—or fixed in place—that turns stones, sand, and sticky binder into a hot, workable mix.

Basic Function

The plant heats and dries aggregates like gravel or sand, then coats them with bitumen, a tar-like substance. This creates asphalt concrete, ready for paving. Temperatures hit around 150-180°C to make everything bind right. Without this controlled process, roads would crack fast.

Importance in Construction

Roads aren’t just paths; they’re lifelines for trade and travel. A good mixing plant ensures the asphalt holds up against weather and traffic. For contractors, it means fewer callbacks and happier clients. Plus, it helps meet tight deadlines on big jobs like bridges or airports.

Types of Asphalt Mixing Plants

Not all plants are the same. You pick based on your job size and site. Some suit quick setups; others handle non-stop output.

Batch Type Plants

These work in cycles. They measure materials for each load, heat them, and mix in batches. Great for jobs needing different recipes, like city streets with varying thicknesses.

Batch plants give precise control. You can tweak the mix on the fly. But they might slow down for huge volumes.

Continuous Type Plants

Here, everything flows steady. Aggregates go through a drum dryer, get coated with bitumen, and out comes the mix without stops. Ideal for long highways where you need tons fast.

They run efficient for big projects. Less waste too, since no batch waits. Drawback? Harder to change mixes mid-run.

Stationary vs. Mobile Plants

Stationary ones stay put, often at quarries. They’re built tough for steady work.

Mobile versions move easy, on trailers. Perfect for remote sites or short jobs. Set up quick, tear down fast.

| Type | Best For | Pros | Cons |

| Batch | Varied mixes | Precision | Slower for large volumes |

| Continuous | High output | Efficient flow | Less flexible |

| Stationary | Permanent sites | Durable | Hard to relocate |

| Mobile | On-the-go jobs | Portable | Smaller capacity |

Choose what fits your crew’s needs. A mismatch wastes time and cash.

Key Components of an Asphalt Mixing Plant

These plants pack smart parts that work together. Each piece keeps the mix consistent.

Feeding System

Cold bins hold aggregates. Conveyor belts feed them at set rates. Keeps the flow even.

Drying and Heating Unit

A rotating drum dries materials with hot air from a burner. Gets rid of moisture so the mix sticks well.

Mixing Chamber

Where magic happens. Hot aggregates meet bitumen and fillers. Paddles stir it all uniform.

Storage and Control

Silos keep the hot mix ready. A control panel watches everything—temps, weights, speeds. Modern ones use computers for accuracy.

- Dust collectors: Catch fine particles, keep air clean.

- Bitumen tanks: Store and heat the binder.

- Filler silos: Add powders for strength.

Without these, the plant falters. Good parts mean reliable output.

The Working Process Step by Step

How does it all come together? It’s a chain of actions.

- Load aggregates into bins. Sort by size.

- Convey to the dryer. Heat blasts moisture away.

- Screen hot materials. Separate for right proportions.

- Store in hot bins briefly.

- Weigh and drop into mixer with hot bitumen.

- Blend thoroughly. Usually 30-60 seconds.

- Discharge to trucks or silos.

Simple, right? But timing matters. Too hot, and it burns; too cool, and it clumps.

For continuous plants, steps merge into one flow. No pauses.

Watch for blockages. Regular checks keep things smooth.

Benefits of Using Asphalt Mixing Plants

Why bother with these machines? They boost your work in real ways.

Quality and Consistency

Hand-mixing? Uneven results. Plants measure exact, so every load matches. Roads last longer, fewer repairs.

Speed on Jobs

Produce hundreds of tons per hour. Finish paving quicker. For busy contractors, that means more projects, better rep.

Cost Savings

Less labor needed. Fuel use drops with efficient burners. Recycle old asphalt too, cutting material bills.

Eco-Friendly Side

Modern plants cut emissions. Dust systems protect air. Some reuse waste heat. Shows clients you care about green practices.

- Safer sites: Less manual handling.

- Versatile: Handle special mixes like porous asphalt.

In short, they build your brand as a pro who delivers top-notch work.

Factors to Consider When Choosing One

Picking a plant? Think ahead.

Capacity Needs

How much mix per day? Small jobs need compact units; big ones, high-output.

Site Conditions

Space tight? Go mobile.

Budget and Long-Term Use

Upfront cost vs. running expenses. Factor in parts availability.

Ask: Does it meet local rules on noise and fumes?

Test runs help. Talk to users for real feedback.

Maintenance and Safety Tips

Keep your plant running strong. Neglect it, and downtime hits hard.

Daily Routines

Check belts and bearings. Clean filters. Look for leaks.

Scheduled Overhauls

Change oils yearly. Inspect drums for wear.

Safety first. Train crews on controls. Use guards around hot zones. Lock out power during fixes.

- Wear PPE: Gloves, helmets.

- Monitor emissions: Stay under limits.

- Log issues: Spot patterns early.

Good habits extend life, cut risks. Your team stays safe, projects on track.

Meet MachPlaza: Your Trusted Asphalt Mixing Plant Supplier

As a top exporter of construction gear from China, MachPlaza focuses on road machinery like asphalt mixing plants. We offer full units, spare parts, and add-ons at fair prices with quick shipping. Our crew handles everything from advice before you buy to support after. With strong ties to suppliers, we customize for your needs. We aim for lasting partnerships, helping you get reliable tools that fit global jobs.

Conclusion

Grasping what an asphalt mixing plant is shows its value in strong, smooth roads. From types and parts to daily runs, these machines drive efficiency and quality. They help contractors stand out, win bids, and grow. If road building is your field, dive deeper— it pays off.

FAQs

What is an asphalt mixing plant and how does it work?

An asphalt mixing plant blends aggregates with bitumen to make road material. It heats, dries, and mixes in steps for a uniform product.

Why choose a batch type when asking what is an asphalt mixing plant?

Batch types allow custom mixes for varied jobs. They suit projects needing flexibility over speed.

What is an asphalt mixing plant’s role in eco-friendly construction?

It cuts waste through precise blending and recycling. Modern ones trap dust and lower fuel use.

How do I maintain one after learning what is an asphalt mixing plant?

Clean daily, check parts weekly. Schedule deep fixes to avoid breakdowns.

What is an asphalt mixing plant best for in small projects?

Mobile versions work well. They’re easy to move and set up for short-term sites.